The progress of modern energy networks relies on precision, endurance, and international compliance—principles embodied by Naishi Trunnion Mounted Ball Valve Factory. From natural gas transportation to underground energy storage, its valve systems form an essential part of the infrastructure that powers industries and communities. Each valve is more than a mechanical device; it is a certified assurance that stability, safety, and global standards are woven into every operation.

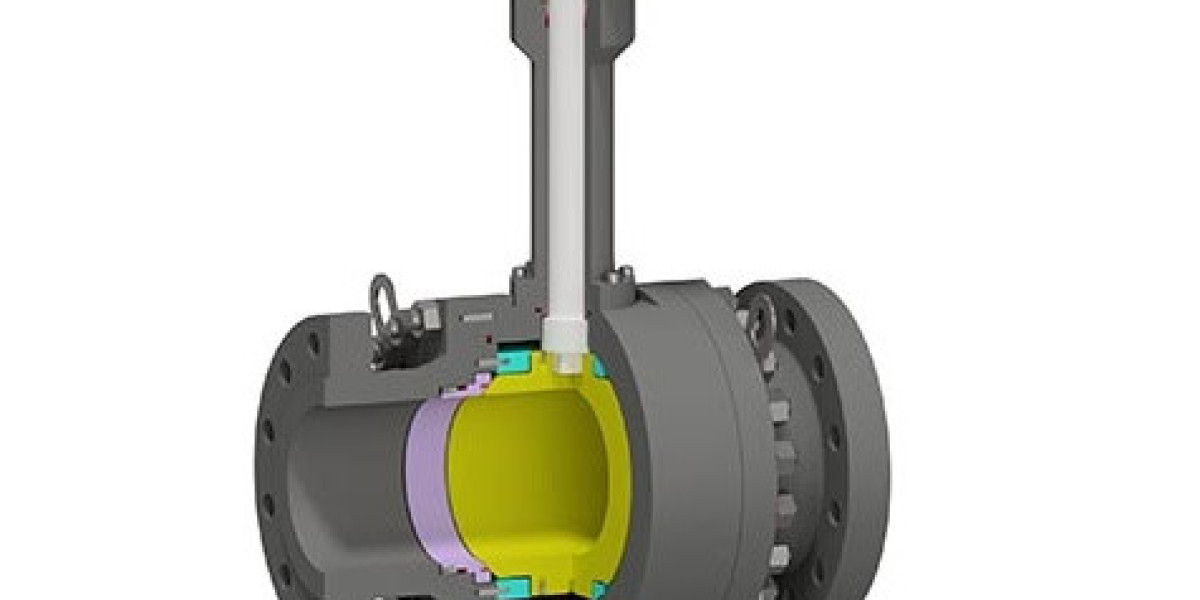

Energy infrastructure demands unwavering consistency. Pipelines cross borders, climates shift, and materials face constant exposure to pressure, vibration, and corrosive elements. To withstand these variables, every valve is developed with high-strength alloys and fully welded integrity. The trunnion-mounted configuration stabilizes the core structure, ensuring pressure balance and mechanical strength even under fluctuating thermal conditions. This design philosophy transforms infrastructure reliability from a goal into a guarantee.

Certification is the language of global trust. Each product undergoes multi-level testing and meets the specifications of major international standards such as ISO, API, and CE. These certifications represent more than compliance—they signify a system of quality control that ensures each component's compatibility with the safety requirements of energy projects worldwide. Through rigorous documentation, dimensional inspection, and traceability, every valve becomes a verified instrument of dependability.

The integration of certification into manufacturing is a process of discipline. Engineers maintain material records, weld procedure qualifications, and pressure test data that confirm the reliability of every unit. This systematic validation builds the foundation for international collaboration, enabling large-scale energy companies to adopt solutions that meet both regulatory and environmental expectations. Beyond documentation lies the real test—performance under pressure. Fully welded trunnion-mounted valves are trusted in remote pipeline stations, refineries, and subsea networks where maintenance access is limited. The ability to maintain leak-proof integrity and consistent torque under such conditions defines not only compliance but mastery in engineering execution.

The global energy transition increasingly depends on technologies that are efficient, durable, and traceable. Combining manufacturing precision with certified assurance, these valves stand as silent enablers of progress—tools that sustain the infrastructure driving industrial development and sustainable growth.For those advancing secure and reliable energy systems, the commitment of Naishi Trunnion Mounted Ball Valve Factory can be explored at https://www.ncevalve.com/product/fully-welded-ball-valve-1/fully-welded-trunnion-mounted-valve.html